Introduction

The bonded magnet market is an essential segment within the global magnetic materials industry, supporting various high-performance applications in electronics, automotive, industrial, and consumer sectors. Bonded magnets are composite materials made by combining magnetic powders with a binding matrix, typically through injection molding, extrusion, or compression bonding techniques. These magnets offer design flexibility, cost-effectiveness, and uniform magnetization properties, making them increasingly vital in miniaturized and energy-efficient systems. As demand for compact and lightweight magnetic components grows, the bonded magnet market continues to gain momentum across global industries.

Growing Demand in Automotive Applications

The automotive industry is one of the most significant consumers of bonded magnets, particularly for use in sensors, actuators, motors, and electric power steering systems. The transition to electric vehicles (EVs) and hybrid models further amplifies this demand, as bonded magnets support lightweight motor components that improve vehicle efficiency. Their ability to be molded into complex shapes also enables automakers to meet space-saving requirements without compromising magnetic performance.

Widespread Adoption in Consumer Electronics

Bonded magnets are commonly used in the manufacturing of miniature motors for consumer electronics such as smartphones, headphones, printers, and smartwatches. Their consistent performance, ease of manufacturing, and ability to achieve tight dimensional tolerances make them ideal for high-volume electronic devices. As the Internet of Things (IoT) continues to expand, the need for compact magnetic components will drive the adoption of bonded magnets in connected devices.

Advantages Over Sintered Magnets

Bonded magnets offer several benefits over their sintered counterparts, including reduced weight, corrosion resistance, isotropic properties, and the ability to produce complex geometries. Unlike sintered magnets, bonded types can be molded directly into their final shapes, eliminating the need for additional machining. This manufacturing efficiency leads to lower production costs and shorter lead times, making them suitable for large-scale applications.

Technological Advancements and Material Innovation

Ongoing research in polymer composites and magnetic powders is resulting in improved bonded magnet performance. Innovations in rare-earth bonded magnets, such as those containing neodymium-iron-boron (NdFeB) powders, are enhancing magnetic strength while maintaining flexibility and thermal stability. These advancements are expanding the scope of bonded magnets into high-temperature and demanding industrial environments.

Increased Use in Industrial Automation

The rise of industrial automation and robotics has created a growing market for compact, high-torque motors that rely on bonded magnets. These magnets enable precise motion control and low-energy operation in robotic arms, conveyors, and automated assembly systems. Their uniform magnetization and reliability make them well-suited for continuous-duty operations in manufacturing settings.

Cost-Efficient Production for Mass Manufacturing

Bonded magnets are particularly advantageous for applications requiring high-volume production with consistent quality. Their low tooling costs, short cycle times, and compatibility with automated molding techniques contribute to economical mass manufacturing. This cost-effectiveness makes them attractive to manufacturers looking to reduce overhead while meeting high-demand specifications.

Sustainability and Recycling Potential

As environmental concerns grow, the bonded magnet market is exploring sustainable practices such as recycling magnetic powders and using biodegradable or recyclable binders. Compared to traditional magnetic materials, bonded magnets offer reduced material waste during production. Industry players are also working on reclaiming rare-earth materials from used magnets to support a circular economy.

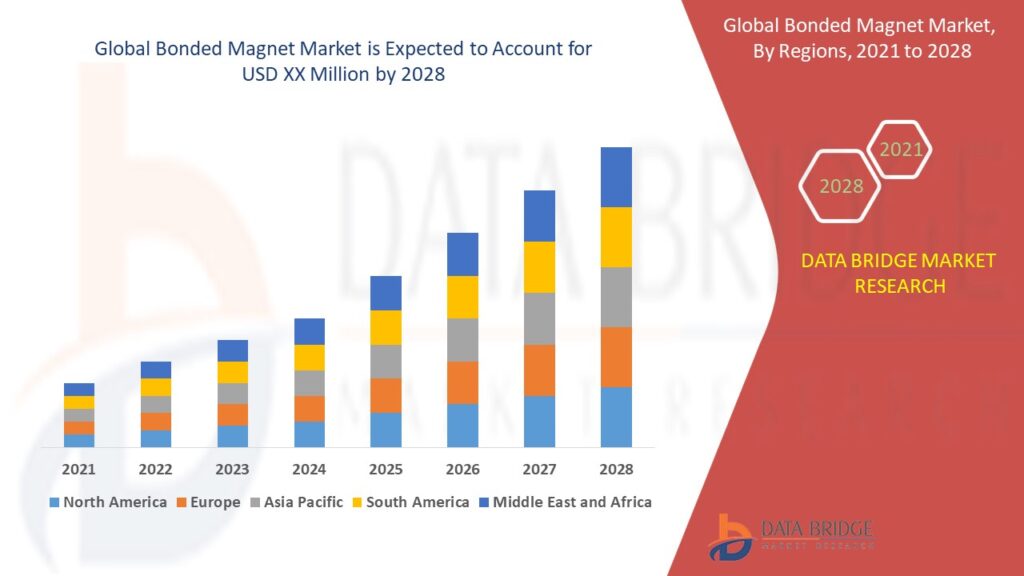

Regional Market Dynamics

Asia-Pacific dominates the bonded magnet market, driven by strong demand from automotive, electronics, and industrial equipment manufacturers in China, Japan, South Korea, and India. The region’s advanced manufacturing capabilities and cost advantages position it as a global production hub. North America and Europe are witnessing moderate growth, supported by technological innovation, electric vehicle expansion, and investments in automation. Emerging markets in Latin America and the Middle East are showing potential due to increasing industrialization and infrastructure development.

Challenges and Limitations

Despite their advantages, bonded magnets face some limitations such as lower magnetic strength compared to sintered magnets, especially in high-performance applications. Thermal stability can also be a concern in environments with extreme heat. Moreover, the fluctuating availability and cost of rare-earth elements may impact production planning and pricing strategies for bonded magnet manufacturers.

Future Outlook and Growth Opportunities

The bonded magnet market is poised for sustained growth due to its adaptability, expanding applications, and evolving material science. With increasing focus on electric mobility, automation, and miniaturization, demand for high-precision, lightweight magnetic components will continue to rise. Opportunities lie in developing high-temperature resistant materials, increasing automation in production lines, and fostering collaborations between magnet producers and end-use industries.

https://www.databridgemarketresearch.com/reports/global-bonded-magnet-market

Conclusion

Bonded magnets are becoming integral to modern engineering solutions due to their design flexibility, ease of manufacturing, and cost efficiency. As industries seek compact, reliable, and high-performance magnetic materials, bonded magnets stand out as a versatile choice across applications. With continuous innovation in materials and processes, the bonded magnet market is well-positioned to support the next wave of technological advancements across multiple sectors.